3 weeks deep, and the projects keep coming! 6/21/2012

I’m getting much more involved with the different areas of Accumold, and as I put things together, I can really see the connections that make things work so smoothly.

I see many connections between jobs here at Accumold and the essential skills and concepts in math. First of all, numbers are everywhere—product numbers, mold numbers, amount of products, types of raw material, sizes, pressures, temperatures, and I could go on and on. Having the ability to differentiate between numbers is a very baseline skill around here. One of the most important jobs at Accumold is measuring parts to make sure they’re within the specifications provided by a customer. Not only is measurement involved, but they take that essential skill to the next level and incorporate number reasoning. An employee must read a control plan and reason to determine if a measurement fits within the specification. A part we used the other day, for example, measured .0391”, the employee had to determine whether that satisfied the required specification of .04” ± .002”. Yesterday I had the opportunity to meet with the guy who runs the wire tool room. He uses some incredible technology that has the ability to use an electric charge along a wire to cut steel with precision for the plastic molds. His software involves a large amount of geometry—odd shapes, slopes, and angles all over the place. Another essential skill very present at Accumold is data analysis by recognizing ideal injection parameters (pressure, speed, temperature, timing, etc.), recognizing errors, and trends with non-conforming parts. As for functions, functions are all over the place. In school, I’ve spent many hours drawing up function machines with my students, and it’s quite humorous for me to envision an injection molding machine as just a fancy function. Each input produces one output. If you put in the same material into the same machine, but something different comes out (a different part), that would be bad as it wouldn’t be a function! I’m super excited to use this as a new function example for next year! J

Along with the essential skills in math, there are also numerous 21st century skills necessary. The biggest one that comes to mind is problem solving. It’s imperative at Accumold, and I think it’s a life lesson that never quite goes away. Being able to recognize a problem and execute a plan in order to achieve success is such a huge task. Whether employees are trying to fix a machine, the leader teams are discussing part problems, or techs are attempting to fix an ongoing measurement issue—problem solving is everywhere! Along with problem solving oftentimes come social interactions. I’ve heard that businesses of today are noticing that younger employees are lacking collaborative skills. I don’t think solitary work would be acceptable around here. Having the ability to talk to a coworker, share ideas, and collaborate is one reason why I think Accumold is having such great success. The employees work together, cross-departmentally, to make sure things run smoothly. Then there’s also the use of technology, another 21st century skill. Since everything is run by machines, with computers and software, technological literacy is a must. I’m fairly confident that every position at Accumold requires some use of technology---computer, email, processing software, microscope, tool scope, and I think I could go on for days. Technology is only getting more intense, and it’s important that an employee be comfortable with his/her surroundings.

As I put together an orientation plan (first day of training) for a new employee, I’m trying to incorporate one of the characteristics of effective teaching—teaching for understanding. Under the current training program, a new employee jumps right out onto the floor and follows around an experienced employee as he/she explains what takes place on the job. Although jumping right into it may sometimes seem like the most beneficial, to actually teach for understanding, there’s more that comes into play. For the first day, I’ve incorporated some videos, handouts, writing opportunities, and time to go out and watch what’s taking place on the floor. The new employee will hopefully not feel totally overwhelmed by just following around the experienced, but will rather receive information about a wide variety of topics, along with some time spent in his/her element on the floor. Another characteristic of effective teaching is formative assessment. I’ve been doing this through my measurement testing. I did a little check with everyone individually to see who could properly use the measurement tools. It wasn’t used as a pass-or-fire test, but rather as an opportunity for growth and improvement.

A few of the standards for mathematical practice that stand out are using appropriate tools strategically and attending to precision. Knowing which tool to use when measuring a part can save a lot of time and hassle. A caliper, micrometer, tool scope (sometimes a fixture can help), Go/NoGo, and drop indicator all serve their own purpose. Some are more effective than others for particular parts. Along those same lines, attending to precision is a non-negotiable. When talking about differences between thousandths or even ten-thousandths of an inch, there’s not much room for approximating and guessing.

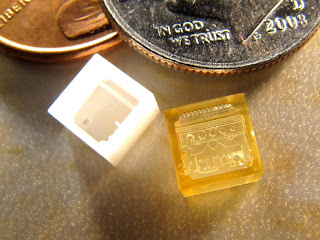

I’m recognizing that throughout my writing, there are quite a few parts that I claim to be “very important” or a “key to success”. I think this is largely because the entire process of manufacturing these tiny parts still blows my mind. As I get deeper into the process, getting more familiar with the injection molding machine and steel mold/tool creation, my mind isn’t getting put to ease. The intricate detail of each and every step is just phenomenal.